Mitaka has been manufacturing precision instruments that are loaded with space hardware technology. And, these instruments function as “standard” in various industries. Above all, non-contact 3D measuring instruments with laser autofocus systems are disseminated widely in domestic semiconductor industry and ultraprecision processing field in Japan. And this laser autofocus system was named as “point autofocus profiling” and registered in ISO 25178 (International Standard of 3D profile and surface texture) as one of Japanese measuring technology in 2008. The point autofocus profiling is officially standardized as ISO 25178-605 (Point autofocus probe) in 2014. Mitaka continues to offer this “brand-new” technology to the world.

Measuring instruments

Faster, easier, more precise

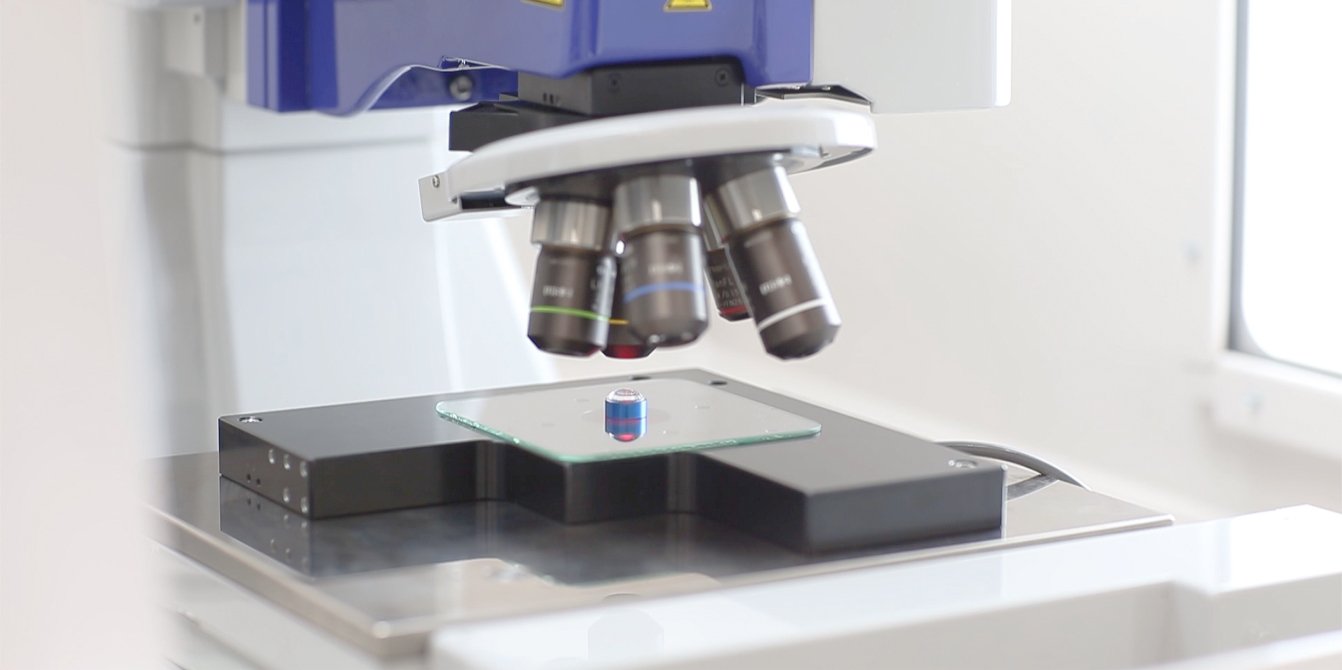

PF Series

Scan AF function offers large measuring area in high speed

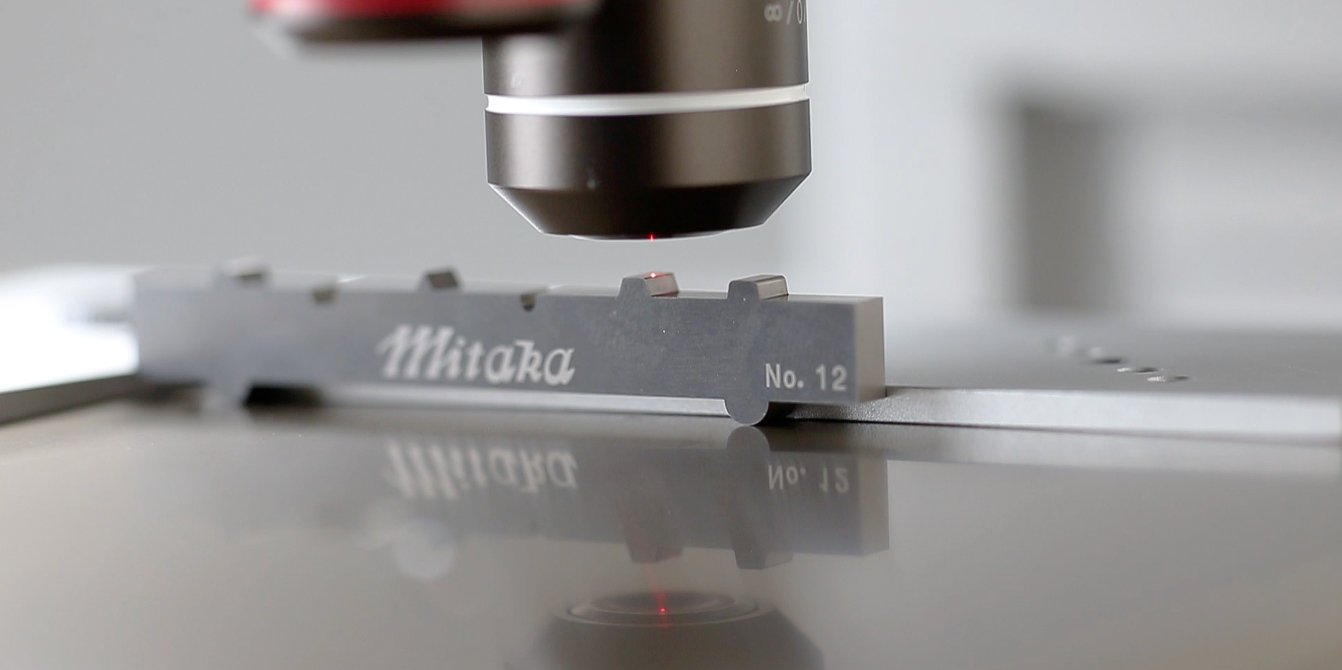

Point autofocus probe 3D measuring instrument

NH Series

Standard model of NH-Series

3D FORM MEASURING INSTRUMENT

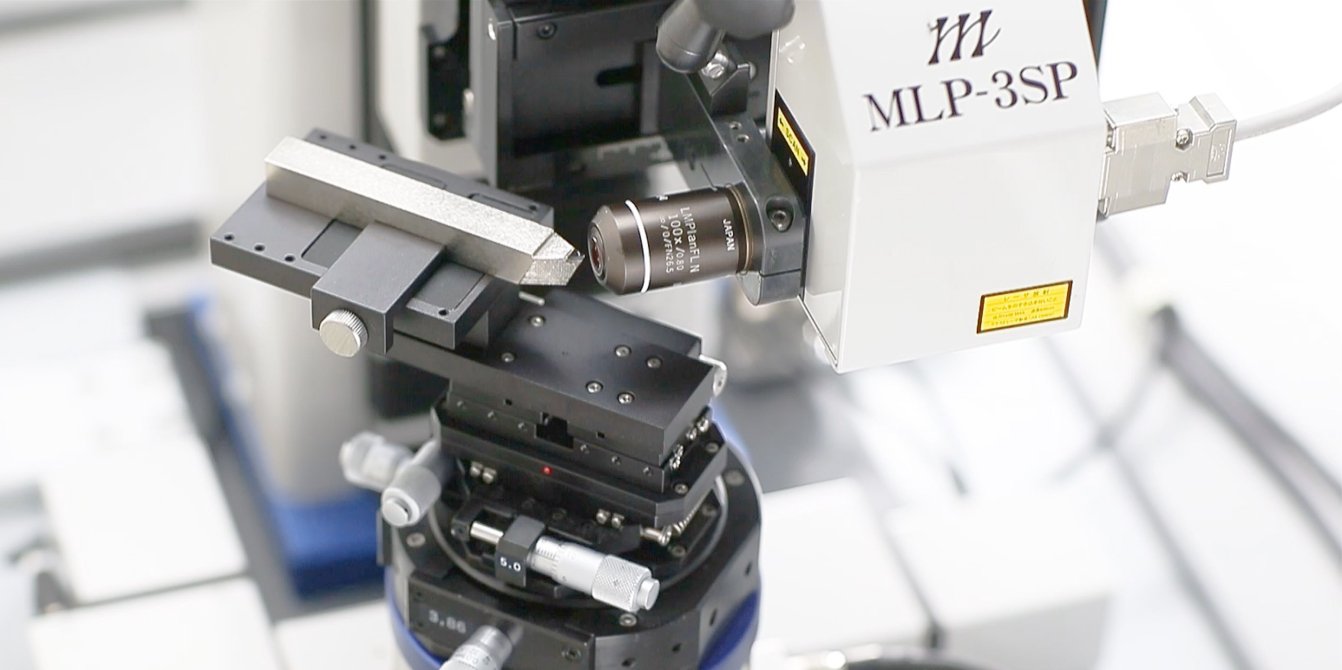

MLP Series

Non-contact measuring instrument

3D measuring instrument

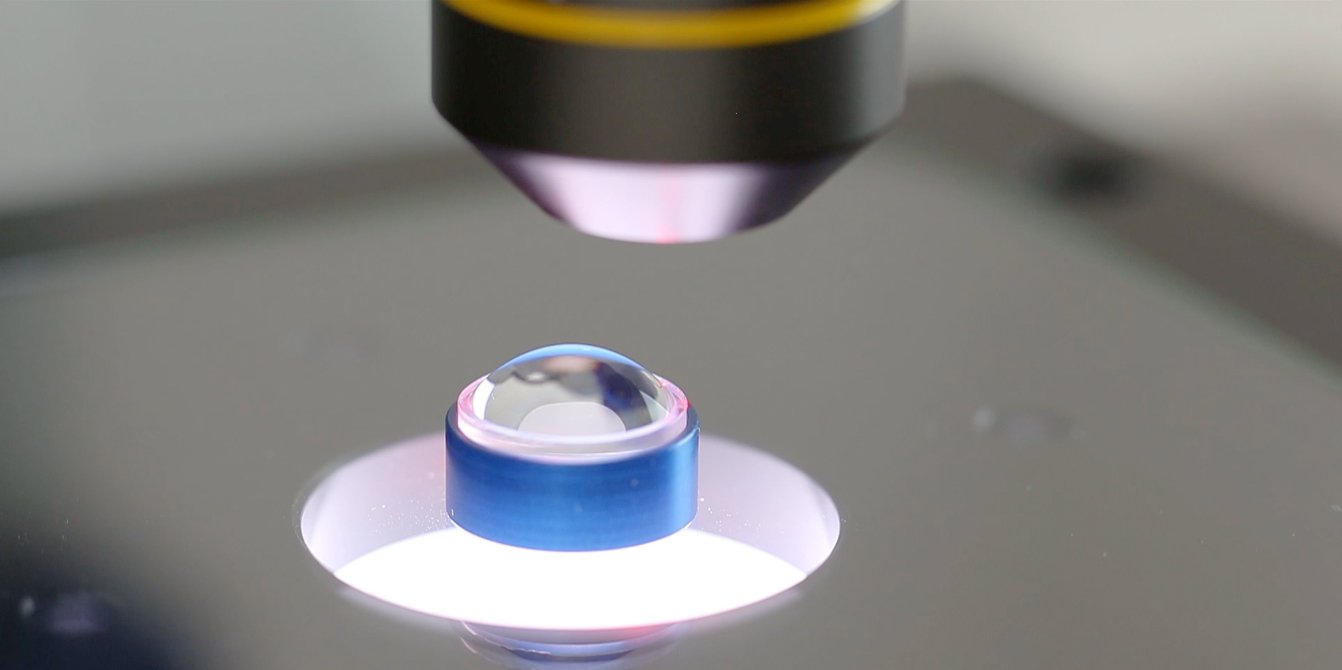

MA Series

Microlens array form measuring and optical characteristic evaluation instrument

Laser probe unit

MP Series

Applications for laser probe unit