Features

Point autofocus probe measurement defies the current conventional non-contact measurement.

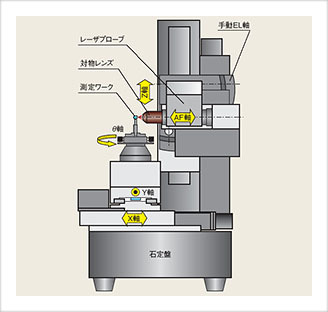

Mechanical drawing of MLP-2

Mechanical drawing of MLP-2

Steep angle measurement

Point autofocus probe tracks steep angles that many non-contact measuring instruments cannot measure. For wokpieces having surface roughness, it tracks a steep angle close to 90 degrees precisely.

High precision measurement

Point autofocus probe optical system and high-sensitive AF sensor enable to measure various workpiece surfaces. It directly measures from a plastic part with 3% light reflectance to a metal part and also mirror surface with over 90% light reflectance.

Comparison on PTB roughness standard material, type D1

Comparison on PTB roughness standard material, type D1

A high correlation with stylus instruments

Point autofocus probe has a 1µm*1 laser spot which offers roughness measurement having excellent correlation with stylus instruments. (Roughness evaluation based on ISO 4287:1997)

*1 @ 100X objective (NA=0.8)

Large measuring area and high precision measurement.

Scanning point autofocus probe mechanism offers measurement in sub-micrometer accuracy.

- Measuring range: below φ80mm

- Resolution: In the AF axis direction: 0.01μm, In the radial direction: 0.1μm

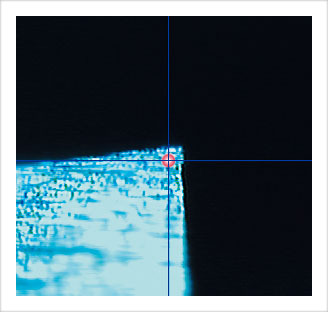

Observation of the actual measuring point

Observation of the actual measuring point

Observation of the actual measuring point.

Point autofocus probe optical system has a built-in CCD camera which offers visualization of the laser spot at the actual measuring point and the workpiece surface.

Since the built-in CCD camera helps an operator find the exact place he/she wants to measure, MLP-2 Series offers easy measurements of micro parts and complex shape workpieces.

360° all around measurement

5-axis control offers omnidirectional approach for measuring workpieces with complex shapes such as punches, end mills, profile shifted gears having steep slopes, etc.

- Home

- Products

- Industrial Equipment

- MLP Series

- Features