Scan AF function offers large measuring area in high speed!

Scan AF function which provides 50 times faster measuring speed than Mitaka conventional measuring speed and the high precision XY scanning stage offer a large measuring area of several tens of millimeters down to the sub micrometer level. PF-60 is perfect for warpage measurement of precision processing parts, molding defects, wear volume and scratch of quantitative evaluations in tribology.

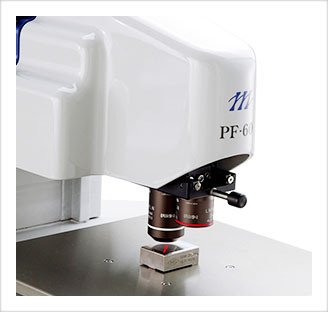

PF-60 “Point Autofocus Probe Surface Texture Measuring Instrument”

Scan autofocus (Scan AF) system offers fast measurement and has large measuring area with high accuracy in the sub-micrometer level

Features

Scan AF head

Scan AF head

- large measuring areas and high precision measurement

(measuring range: XYZ=60x60x10mm, positioning resolution: XY=0.1µm, Z=0.01µm) - fast measurement with Scan AF

- high correlation with the international standards for roughness measurement

- MitakMap, standard feature software, evaluates 2D and 3D roughness / surface texture based on the ISO Standard

- compact in size which requires a small space for installation

(required space for installation: 400mm x 400mm) - instrument weight: 31kg

Specification

- moving range (X, Y, Z) = 60 x 60 x 60mm

- X-Y axes positioning resolution= 0.1µm

- Z axis positioning resolution = 0.01µm

- laser spot diameter = 1µm (with 100X)

- laser: semiconductor laser (o/p: 1mW Max. λ= 635nm)

Measurement example that PF-60 is perfect for

Wear volume of brake pad

Separating burr / contact surface / wearing surface and calculating Abbott-Firestone curve.

Tooth flank of a precision gear

Form measurement and surface roughness evaluation of a precision gear.

Measurable Examples

More Information

We welcome your inquiry by telephone / fax / information request form.

Phone: +81-422-49-1491

Fax: +81-422-49-1117

Contact Us