High precision image processing offers optical characteristics evaluations

MA Series

3D measuring instrument

Microlens array form measuring and optical characteristic evaluation instrument

Features

High precision image processing offers optical characteristics evaluations

Functions : Effective focal length / Back focus / Transmittance / Focal position / Focal depth / MTF

Automatically measures microlens arrays(MLA)

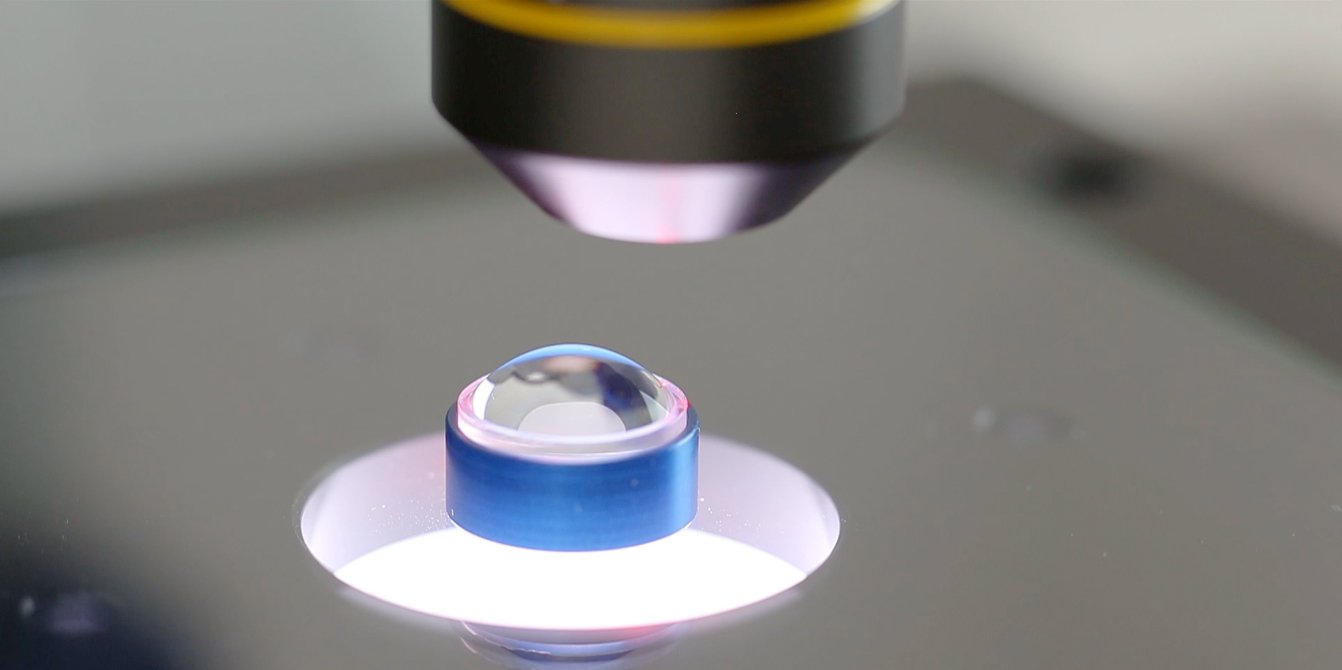

The right figure shows the measurement optical system. The focused image(the pinhole slit image) of the paralle laser beam is enlarged by the microscope lens and is captured by the camera. The image processing evaluates this captured image on its optical characteristics.

Measurement optical system

Automatically measures microlens arrays (MLA)

Matrix measurement software

The specialized matrix measurement software offers automatic measurement of MLA by registering the array patterns

Nomarski interference contrast observation

NH microscope can load Nomarski interference contrast optical system.Nomarski optical system. Nomarski optical system visualizes angstrom-level surface roughness and scratches that normal bright-field optical systems cannot visualize, and offers immediate quantitative measurements of roughness and step heights.

NH-3Ns loaded with Nomarski optical system

Ray diagram of NH Series with Nomarski optical system

Functions

Laser Probe measurement

・Radius of curvature and center coordinates of each lens surface

・Circularity

・Height of apex, XY coordinates

・Cross-sectional and three-dimensional shape measurement, surface roughness measurement

・Circularity

・Height of apex, XY coordinates

・Cross-sectional and three-dimensional shape measurement, surface roughness measurement

Image Processing

・Effective focal length

・Back focus

・Transmittance

・Focal position

・Focal depth (option)

・MTF (option)

・Back focus

・Transmittance

・Focal position

・Focal depth (option)

・MTF (option)

Specifications

Measuring area( X, Y, Z, AF)

100, 100, 100, 10mm

X-Y Axis Linear Scale

0.1μm

AF Axis Linear Scale

0.01μm

Measuring method

Point Autofocus ISO 25178-605

Raser

λ=635nm <1mW

Examples of measurements that this equipment is good at

Examples that can be measured with this equipment

Fresnel lens molding die

Grating

Volume of solder

HDD head suspension

High-density mounting board

Surface of aspherical lens molding die

Fingerprint

Human hair

Unevenness of evaporated metal film

Diamond abrasive grain

Tip of turning tool

BGA

Warpage and waviness of wafer

Grinding work surface

Wear volume of brake pad

Tooth flank of a precision gear

More Information

We welcome your inquiry by telephone / fax / information request form.

- Phone

- +81 422-49-1491

- Fax

- +81 422-49-1117