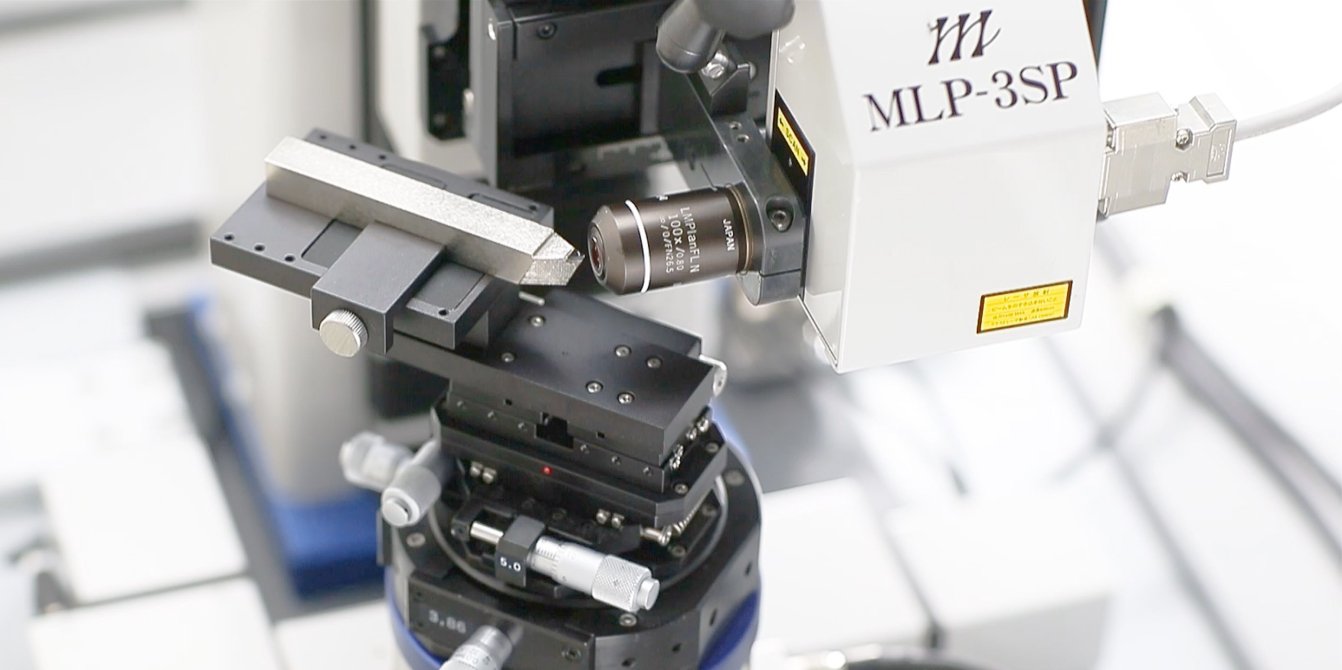

MLP-3 is specialized in complex measurement which none of conventional 3D measuring instruments, profile projectors or laser microscopes could possibly offer - this is the filed in which MLP-3 excels. Point autofocus probe with the 5-axis stage help measures solve problems.

MLP Series

Features

High-precision measurement with no influence of surface colors / reflectance

Approach to a workpiece in various direction

Capable of observing the measurement point

High correlation with international standards for roughness measurement

・Calibration:PTB(Germany)

・Measurement method:stylus

・Tip radius:5μm

・Evaluation length(ln):4mm

・Cutoff value(λc):0.8mm

MLP-3 offers all-round contour measurement

Solution

Problem

Solution

Polygon measurement offers the entire contour measurements of the complex formed workpieces

Problem

Solution

A fully non-contact measurement never damages or deforms the workpiece during the measurement.

It is possible to evaluate product life after taking measurements.

Problem

Solution

MLP-3 offers roughness, form and surface texture measurements.It is possible to carry out size evaluation from a surface texture measurement and to evaluate a surface texture by removing a geometric form from it.

Problem

Solution

Not only can MLP-3 evaluate the form of the entire tool but also it can precisely measure its cutting edge.End mill measurement support software (option) automatically detects the cutting edges and the tips of the tool which offers a simple operation and minimize the variability in data caused by measuring different positions.

Problem

Solution

MLP-3 directly measure inner/outer contours in a large area in submicron accuracy. Inner diameter measuring module (option) offers fitting evaluation and DXF comparison by using the standard evaluation software.

Measurement

Specification

Measuring area( X, Y, Z, AF)

120 × 120 × 130 × 40mm

X-Y Axis Linear Scale

0.1μm

AF Axis Linear Scale

0.01μm

Measuring method

Point autofocus profiling ISO 25178-605

Laser

λ=635nm <1mW

Examples of measurements that this equipment is good at

Tip of turning tool

Plastic gear

Microgear

Internal gear

End mill measurement

Precision micro punch

Contour form and edge measurements of drill

Ultraprecision machining tool (Diamond Round cutting tool)

Examples that can be measured with this equipment

Fresnel lens molding die

Grating

Volume of solder

Microlens array

HDD head suspension

High-density mounting board

Surface of aspherical lens molding die

Fingerprint

Human hair

Unevenness of evaporated metal film

Diamond abrasive grain

BGA

Warpage and waviness of wafer

Grinding work surface

Wear volume of brake pad

Tooth flank of a precision gear

More Information

We welcome your inquiry by telephone / fax / information request form.

- Phone

- +81 422-49-1491

- Fax

- +81 422-49-1117