Scan AF function which provides 50 times faster measuring speed than Mitaka conventional measuring speed and the high precision XY scanning stage offer a large measuring area of several tens of millimeters down to the sub micrometer level. PF-60 is perfect for warpage measurement of precision processing parts, molding defects, wear volume and scratch of quantitative evaluations in tribology.

PF Series

Faster, easier, more precise

Scan AF function offers large measuring area in high speed

Features

Large measuring area and high precision measurement

The laser probe with a radius of 0.5µm and the precision xy stage directly measure an area of several tens of millimeters down to the sub-micron level.

fresnel lens X= 4.498mm Y=4.501mm Z=4.733μm

grating X= 4.498mm Y=4.501mm Z=4.733μm

Fast 3D measurement

Fast scanning autofocus (AF) function offers large measuring area and high precision measurement.

The conventional measuring method requires 1 hour and 20 minutes whereas the fast scanning AF function requires only 6 minutes.

The conventional measuring method requires 1 hour and 20 minutes whereas the fast scanning AF function requires only 6 minutes.

roughness standard XY= 0.8mm x 0.8mm

2D measurement: measuring time is only 15 sec. / 8000 points

Excellent angle tracking capability

The highly sensitive autofocus sensor captures low levels of light reflected from the surface of the sample and directly measures steep angles and step heights.

small gear (module: 0.3) X=2mm Y=2mm Z=723μm

Maximum measurable angle : 87 degrees

Easy positioning of the measuring point

User friendly operation offers high precision measurement.

The objective changer switches between a low magnification objective for observation and a high magnification objective for measurement in a single step operation.

The objective changer switches between a low magnification objective for observation and a high magnification objective for measurement in a single step operation.

Objective slider

Measurement window

Measuring method approved by ISO

Our measuring principle is classified in ISO 25178-6 and is documented as ISO 25178-605 (point autofocus probe).

Overview

PF-60 drives its high-precision XY stage to obtain the coordinate values in its full range of movement (60mm x 60mm). There is no need to stitch measured data since PF-60 has no measuring limits, hence it offers high precision measurement of a large area.

Scanning XY stage

PF-60 drives its high-precision XY stage to obtain the coordinate values in its full range of movement (60mm x 60mm). There is no need to stitch measured data since PF-60 has no measuring limits, hence it offers high precision measurement of a large area.

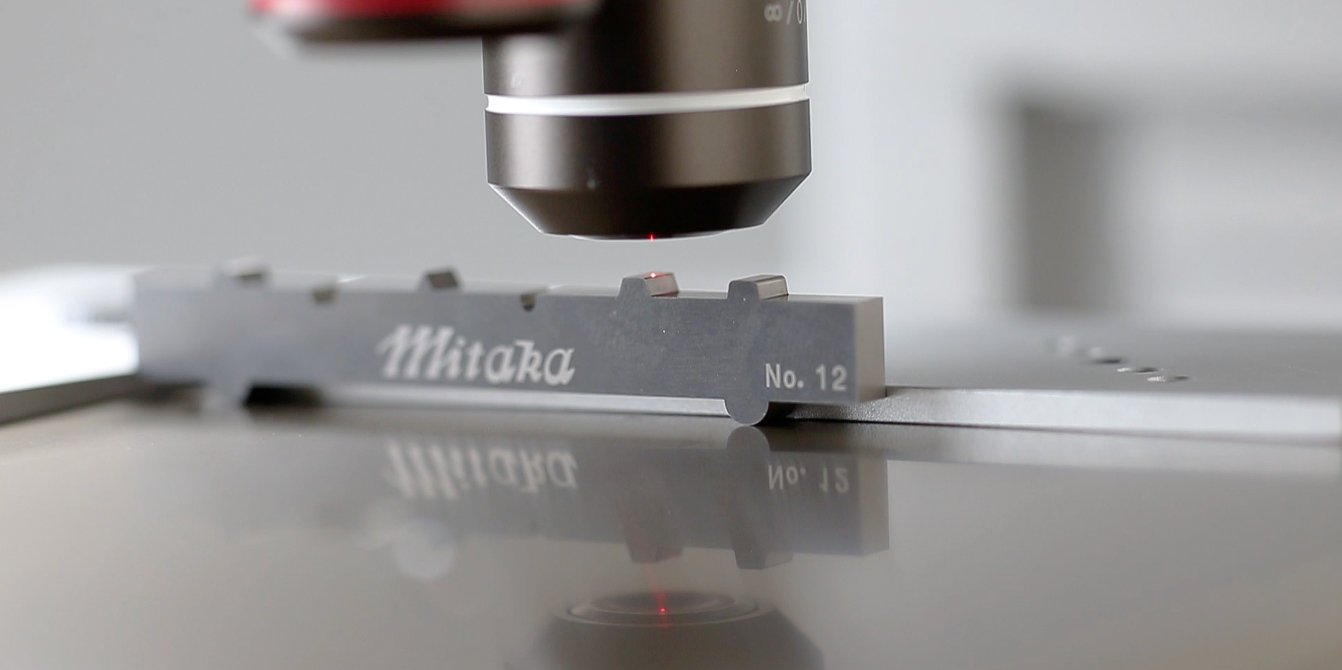

Point autofocus probe

The laser beam incorporated in the AF microscope passes through the objective (indicated by the red line) and forms a laser post on the surface of the sample as a "probe" with a radius of 0.5µm.

The reflected laser beam from the workpiece surface passes through the objective again and forms an image on the autofocus sensor (AF sensor). The AF sensor detects the laser spot displacement in real time and adjusts the AF microscope back to the in-focus position.

The reflected laser beam from the workpiece surface passes through the objective again and forms an image on the autofocus sensor (AF sensor). The AF sensor detects the laser spot displacement in real time and adjusts the AF microscope back to the in-focus position.

High correlation with the international standards for roughness measurement

Point autofocus profiling has a high correlation with roughness standard materials for stylus instruments and obtains reliable data.

・Roughness standard: Type D1 (ISO 5436-1)

・Calibration: PTB

・Measurement method: stylus

・Tip radius: 5µm

・Sampling length (ln): 4mm

・Cutoff value(λc): 0.8mm

・Calibration: PTB

・Measurement method: stylus

・Tip radius: 5µm

・Sampling length (ln): 4mm

・Cutoff value(λc): 0.8mm

Autofocus optical sytem cuts ghost and stray light

The autofocus optical system cuts out unnecessary light to achieve targetted measurement.

Transmissive surface

Secondary reflection of a Vee-groove

Measurement

2D measurement

Directly measure millimeter-order contour shape with a resolution of 0.01µm.

3D measurement and evaluation

PF-60 is immune to surface reflectance and offers high-precision measurement from mirror surfaces to transparent materials.

It also offers high-precision analysis on the obtained data using form removal, extraction of a profile, etc.

It also offers high-precision analysis on the obtained data using form removal, extraction of a profile, etc.

precision molding die

microlens arrays (optical component)

surface defect of a LED lens (optical component)

tip of a turning tool (processing tools)

Image capture

This function displays a monitor image of the measurement area on the PC monitor, the scale and saves the image. This enables not only confirmation of the measurement position and observation of the workpiece surface, but also simple dimensional measurement with the field of view

Specification

Installation size

400mm×400mm

Instrument weight

31kg

Measuring range (X, Y, Z, AF)

60 × 60 × 60 × 10 mm

X-Y-axes scale resolution

0.1μm

AF-axis scale resolution

0.01μm

Measuring method

Point Autofocus ISO 25178-605

Laser

λ=635nm <1mW

Examples of measurements that this equipment is good at

HDD head suspension

Measurement of delicate sample which easily distorts by one gentle touch.

High-density mounting board

Fine structure in a large area.

Fingerprint

High precision measurement of delicate material.

Human hair

Capturing fine structure.

Diamond abrasive grain

Cutting edge profile and projection height measurements.

Tip of turning tool

Offering 3D view, size evaluation and roughness measurement.

Warpage and waviness of wafer

High speed measurement of total warpage and waviness of wafer.

Grinding work surface

測定範囲から面領域粗さ演算も可能

Wear volume of brake pad

Separating burr / contact surface / wearing surface and calculating Abbott-Firestone curve.

Examples that can be measured with this equipment

More Information

We welcome your inquiry by telephone / fax / information request form.

- Phone

- +81 422-49-1491

- Fax

- +81 422-49-1117